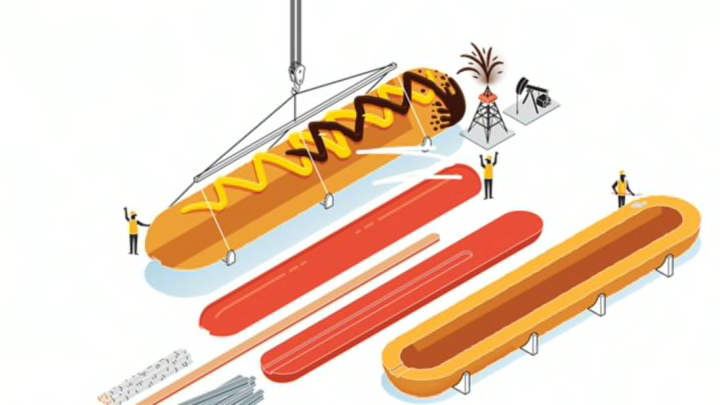

To make the county fair staple, you need ingredients from all over the globe.

1. Eggs

Most eggs come from Leghorn hens. According to Steve Ettlinger’s Twinkie, Deconstructed, they’re cracked in specialty plants like Papetti’s in New Jersey, which breaks nearly 7 million a day! Once liquefied, the eggs are hosed into trucks and shipped off.

Textbook Example

2. Corn Syrup

Yellow # 2 dent field corn puts the “corn” in your corn dog. Corn syrup is made in huge batches: First, 40,000 bushels of corn are soaked in seven-story tanks of hot water for two days. Corn starch is separated from the wet-milled kernels, centrifuged, and washed up to 14 times! Most of the starch is used to make cardboard, but the rest is placed in a vat with hydrochloric acid and heated into corn syrup.

3. SMOKE FLAVORING

Liquid smoke comes from actual smoke! To make it, wood chips or sawdust are burned and the vapor is captured and condensed into a liquid. After the dogs are cooked, they get a quick shower in it.

4. CELLULOSE*

For nearly 6,000 years, people have used animal intestines to encase sausages. But chances are, your frank was wrapped in trees. Wood chips are steamed, saturated in a stew of caustic sodium sulfide, cooked, and screened into wood pulp. The result is cellulose, popular for paper, textiles, and hot dog casings (which are stripped off after the dog is factory cooked).

Textbook Example

5. THIAMINE MONONITRATE (B1)

Although B1 is found in brown rice husks, it’s usually synthesized from petrochemicals derived from coal tar. (It’s easier and cheaper to synthetically create vitamins than to extract them from plants.) Most B1 companies keep the details secret.

6. RIBOFLAVIN (B2)

Your corn dog’s riboflavin comes from either bacteria, yeast, or fungi. Thirty percent of the world’s B2 is made from the fungus Ashbya gossypii. These microbes are dunked in a broth of fermenting fats and carbs, and enzymes secrete B2. Then the vitamin is extracted, crystallized, and powdered.

7. Niacin (B3)

Niacin comes from Switzerland—and petroleum. Swiss petrochemical plants “crack” petroleum into methane, ethylene, and other gases. The methane is concocted into nitric acid, while the ethylene is converted into acetaldehyde. Brewed together with some ammonia sprinkled in, the two make niacin, which enriches flour and safeguards consumers from diseases like pellagra.

8. FOLIC ACID (B9)

Most of the world’s B9 is made in China from a soup of petrochemicals or fermented tapioca starches. The acid is purified with zinc and magnesium (mined from open pits in Australia or China) and powdered.

9. PHOSPHORIC ACID*

Phosphate rocks in Idaho are surface mined and baked to 2,500°F. Then they’re tumbled into a nine-story furnace and liquefied at 11,000°F—the intensity of the sun. Phosphoric acid is made by spraying water onto the gas that escapes.

10. SODIUM BICARBONATE

Gas companies remove CO2 from natural gas and truck it to processors, who clean, compress, and liquefy the gas. The carbon dioxide is added to a slurry of soda ash to make sodium bicarbonate: that is, baking soda.

Textbook Example

11. BAKING POWDER

Limestone—the calcified skeletons of ancient sea critters—is mined deep under Idaho. It’s crushed and heated to about 2,000°F to make lime. Meanwhile, in Wyoming, trona—ancient lake mud—is mined, crushed, and filtered into soda ash, which is used for glassmaking. When both are mixed with phosphoric acid, you get two main compounds in baking powder: sodium acid pyrophosphate and monocalcium phosphate.

12. TRIMMINGS

Unless it’s marked “all beef,” that wiener may contain a whole barnyard: cows, pigs, turkeys, and chickens! Franks can contain tongues, snouts, and lips, but “these components should not exceed 15 to 20 percent of sausage formulation,” says the UN’s Food and Agriculture Organization. (The FAO also requires franks to be free of gristle, sinews, bone, and cartilage). Edible offal aside, most of the dog is made of trimmings—the skeletal meat left over after the prime cuts are made. These are ground up like hamburger meat and then blended into a pudding-like batter with all the air vacuumed out. The gloop is then pumped into casings.

Textbook Example

13. WHEY

A cheap replacement for eggs and milk, whey often comes from Wisconsin cheese factories. To make cheese, a culture of bacteria is added to milk to make it sour. Enzymes thicken the mix; after two hours, the resulting curds are pressed into cheese. The residual liquid whey is siphoned off, dried, and powdered.

14. BLEACH*

The U.S. makes 26 billion pounds of chlorine each year—some of which is used to bleach flour. To make chlorine, saltwater is exposed to a strong electrical current. The jolt separates the sodium, and the resulting chlorine is purified, compressed, and liquefied. Then it’s shipped in bulletproof tanks to flour mills, where it’s stirred in to balance the powder’s pH. (This keeps future batches of bread light and fluffy.)

15. POTASSIUM LACTATE

The potassium in your corn dog—and your fertilizer—is unearthed in Canada, from 3,000 feet underground. There, potash is mined and baked in a kiln to make pearl ash. This is mixed with slaked lime to create potassium hydroxide, which is added to a soup of lactic acid—derived from sugar cane or beets. The result is potassium lactate, an additive used to extend the shelf life of meat.

16. IRON

The iron we eat comes from oil wells and ore mines. Refineries extract sulfur from “sour” crude oil and convert it into sulfuric acid. The acid is shipped to steel mills, where freshly made steel is “pickled” in an acid bath. As iron saturates the acid, crystals of iron sulfate sink—these are powdered and mixed into flour to protect eaters from deficiency-related ailments like anemia.

Textbook Example

17. STICKS*

Your corn dog stick started as a Canadian white birch tree. The tree, which has pale peeling bark, is flavorless and odorless—perfect for popsicle sticks, toothpicks, and chopsticks. The wood is flattened into thin, paperlike scrolls and sticks are punched out with a die-cut machine.

*You do not consume this; it's merely part of the corn-dog-making process.