Water has long been the limiting factor for humans in space. But now, NASA is developing a rover that can make water on the Moon. Such a capability will be necessary for any serious attempt at the permanent settlement of Mars, or any other long-term space voyage. If successful, it will inaugurate a new, critical area in space exploration, where resources from other worlds can be harnessed and used.

Presently, everything we use in space is made on Earth. Consider the big, visible parts of human exploration of the solar system, rockets like the Space Launch System (SLS), under construction and set for its maiden voyage in 2018. There’s also the Orion capsule, tested previously and set to fly atop SLS (without astronauts). Then there’s work on habitats: Scientists are currently working on manufacturing artificial habitats for the International Space Station, but soon will be working on one for the Martian surface. A huge part of this kind of pioneering the solar system, however, concerns not just what we bring to other worlds, but what we leave behind. The Lunar Resource Prospector is the first big step in striking that balance.

IN-SITU RESOURCE UTILIZATION

The real problem of colonization is mass. It's very expensive to send something to space, and the heavier it is, the more it costs. It takes hundreds of kilograms on the launch pad to put a single kilogram on the surface of Mars, and Martian settlers will need many, many metric tons of commodities to survive. Practically speaking, they can't take everything they will need from Earth. To colonize the solar system, they will have to learn how to use the resources of the solar system.

The good news is that everything in the solar system is a potential resource for settlers. In-situ resource utilization, or ISRU, is the concept of mining resources on other worlds and turning them into useful commodities, as well as recycling waste created on other worlds. (Waste conversion solves two problems: It creates new useful things and eliminates garbage. The ISS dumps its garbage, allowing it to burn up in the atmosphere. But surface dwellers on Mars won't have such a convenient disposal service.)

Energy is an important part of ISRU, and from a settlement perspective, energy is very cheap. The Sun is a giant fusion reactor in the sky, after all, and to harness it, all pioneers need are a few solar panels that they bring from home. Those panels will provide energy for a very long time—energy that can be used for ISRU.

Mars is the most likely current spot for future human settlement, so consider what resources might be available there: Settlers could extract oxygen from Mars's soil, known as regolith. Water could be extracted from volatiles in the soil, essentially baking them off. There is also carbon dioxide in the Martian atmosphere. Combine carbon with electrolyzed water and settlers can make methane, which could be used as fuel.

Settlers won't need to take building material to Mars; they could easily glue soil together and make bricks. Metals could also be extracted from Martian regolith to build things. Because Mars is rich with carbon, hydrogen, and oxygen, settlers could even make plastic. What would they build first? Probably greenhouses, for starters. Growing crops for food will also be useful for water purification and oxygen generation.

For ISRU to be most effective, planning will begin long before humans leave Earth. NASA's provisional plans see ISRU projects beginning 480 days before astronauts launch. Machines already on Mars will be put to work before settlers even arrive, extracting resources and storing them cryogenically. Water will need to be waiting for humans to drink. Oxygen and inert gasses would need to be ready for instant use in a habitat. An ascent vehicle would be fueled with methane propellant and ready from day one in the event of an emergency.

Even the propellant to get to Mars in the first place could be extracted off-world. The moon's equatorial region yields an abundance of oxygen, and its poles an abundance of water. Engineers could harness that to make rocket propellant, which would be much cheaper to bring from the Moon than launching it from Earth.

ISRU is an obvious approach to exploration and settlement, but so far, it’s been theoretical: No one has ever tried this on a planetary scale. When we go to Mars, it won’t be for a casual visit, it will be for pioneering. The long-term goal is independence from Earth.

LUNAR RESOURCE PROSPECTOR

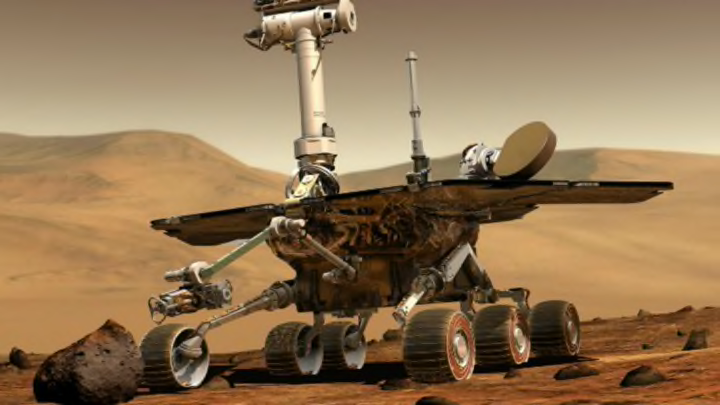

One of the first serious ISRU proposals is the Lunar Resource Prospector. The project is in early development and will be NASA's first soft landing on the Moon since the 1970s. The spacecraft is a small rover, and as its name suggests, it will prospect the lunar surface, studying its composition with an emphasis on finding water.

Scientists will choose its landing site carefully. Potential sites must be in sunlight, as the spacecraft is solar powered, and it must have a direct line of sight for communications with the Earth. (It does not presently use orbital assets as relays.) The terrain must be traversable, and data collected by such spacecraft as the Lunar Reconnaissance Orbiter will have to suggest where there is hydrogen present in the subsurface, and where subsurface temperatures support the presence of water. Moreover, the landing site must be close to at least one of the moon's permanently shadowed regions. (There are areas on the moon that have not seen sunlight in billions of years; water is known to exist in such places.) Moreover, the orbit of the Moon and shifting launch windows on Earth mean that different landing sites must be chosen for different times of the year, and that if a launch slips, a backup landing site is ready to go. Sometimes the prospector will target the north pole of the Moon, and sometimes the south pole.

The lander itself is a pallet design—a flatbed from which the rover would roll once it has landed. It would immediately orient its solar panels toward the sun. Because of the rover's relatively small size, the sun provides more than enough energy for its operation, especially when compared with Curiosity on Mars, which is big enough that it needs to be powered by a radioisotope thermoelectric generator. "The rover that we're going to go on is a little bit smaller than a golf cart," James Smith, lead system engineer of the primary payload for the rover, told mental_floss earlier this year. "It's not a MSL [Mars Science Laboratory] sized-rover, but it's much bigger than Pathfinder."

Once the science mission gets underway, a neutron spectrometer on the rover will look for signatures of hydrogen in the lunar subsurface. (Think of a metal detector, only for hydrogen.) This might originate from water, but might also be found in hydrated minerals, or be solar-implanted hydrogen. A drilling instrument will bring regolith material to the surface for quick inspection by a near infrared spectrometer. "A cool thing about this," Jacqueline Quinn, an environmental engineer at Kennedy Space Center, told mental_floss, "is that we're going to get a meter sample, and that's never been done robotically."

The instrument can also grab material and deliver it to an onboard oven. The oven is a sealed system, and through heating can drive off the water. A quantifying spectrometer system can determine the precise amount of water present in the lunar dirt. That water is also imaged and those images are sent back to Earth. For the first time, humans will see video of water extracted on another world.

The rover itself is nimble and engineered to traverse up to a 15-degree slope and not tilt over. The moon's light gravity is an additional engineering challenge. "We have to have equal and opposite forces in one-sixth G," says Quinn. "We have to have enough mass to counter our drilling—otherwise we'll do beautiful doughnuts in the surface. We don't want to do that."

The Lunar Resource Prospector is designed to be launch-vehicle independent. SLS would be an optimal rocket for the mission, and the timing is just right, but the spacecraft's "mass to translunar injection" is such that it can fly on anything from a SpaceX Falcon 9 rocket and up. If all goes well, the mission will launch in the 2020s, and we’ll finally get a chance to see what in-situ resource utilization looks like in practice.