Building a piece of flat-packed furniture from IKEA can be an emotional rollercoaster. It is all worth it in the end, but the process can often seem like cruel and unusual torture by design. In a recent interview with Fast Company, IKEA's deputy packaging manager Allan Dickner admits that the instruction manuals are challenging, but, believe it or not, things could be a lot worse.

"We had one furniture piece, a type of wardrobe, which originally had over 400 fittings and screws to hold it together," Dickner told FastCo, explaining that packaging engineers are responsible for constructing early versions of the retailer's furniture before they settle on an "optimized" design. The "ready-to-assemble" model is one way that IKEA is able to offer its products at such affordable prices, but Dickner says that it's about finding a middle ground. "When it takes someone five hours to build it, you can ask yourself: have you gone too far with the flat packing? It’s always about finding a balance between ease of assembly and optimizing the packaging."

Dickner also explained that the engineers at IKEA use "proven solutions" as a starting point. The "generalized templates" are altered based on the unique specifications of the new product. They are also "algorithmically optimized," and are designed with structures like elevators and staircases in mind.

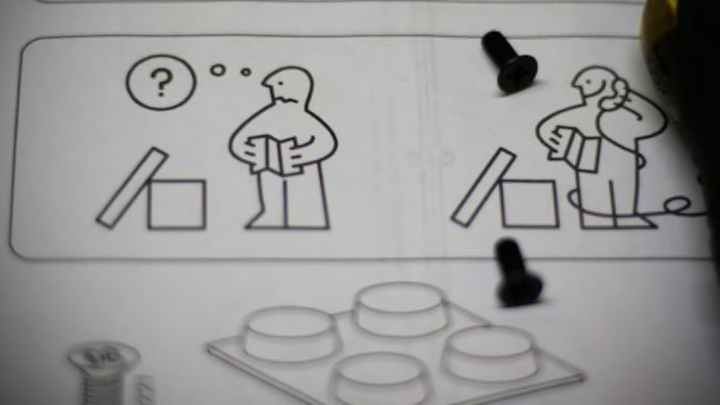

The instructions are made using various resources, including "construction drawings, digital snapshots, 3D models, and videos of test assemblies." According to Jan Fredlund, a designer who works on these manuals, the test assembly phase is key. The "communicators" who design the instructions are tasked with constructing the pieces for themselves to find points where others may be confused and make mistakes.

[h/t: FastCo]