An Espresso Machine Designed for Space Travel

Astronauts orbiting the Earth in the International Space Station often miss the many comforts of home: A warm shower. Family time. And of course, a good cup of joe.

“‘An espresso coffee is what I miss most aboard the International Space Station.’ We have repeatedly heard this comment from the Italian astronauts,” says Italian coffee company Lavazza, which teamed up with aerospace engineering company Argotec to create an espresso machine designed specifically to be used in space. It’s called the ISSpresso (I-S-S for International Space Station. Get it?), and it arrived at its destination this morning, three days after leaving Earth on a SpaceX supply ship. Now astronauts can get a cup of coffee that is “good, hot, and steaming,” says Giuseppe Lavazza, Vice President of Lavazza.

"There's coffee in that nebula"... ehm, I mean... in that #Dragon. pic.twitter.com/9MYrqIOXnI

— Samantha Cristoforetti (@AstroSamantha) April 17, 2015

The first pour will likely go to Italian Air Force Captain Samantha Cristoforetti. She’s been on the ISS for four months already, forced to drink instant coffee which, when you’re used to the glory that is Italian espresso, is torturous. "For an instant coffee, it's an excellent instant coffee," Vickie Kloeris, who manages the space station's food supply for NASA, tells NPR. “Can it compete with brewed espresso? No."

While the ISSpresso machine is specially designed to withstand space conditions, nobody really knows how it will behave. “The principles that regulate the fluid dynamics of liquids and mixtures are very different from those typical on Earth,” Lavazza says. In a normal espresso machine, the tubes that carry water are made of plastic. In the ISSpresso, they’re made of a special steel that can withstand extreme pressure. The machine is roughly the size of a microwave but weighs about 44 pounds.

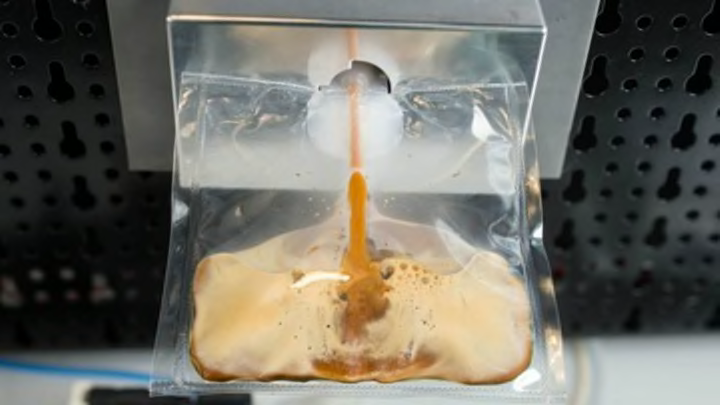

Here’s how it’s supposed to work: A little capsule containing the coffee is installed along with a water bag. When the brew is done, the coffee makes its way into a standard NASA drinking pouch, which can be removed—and voila—espresso in a bag. (They’re working on designing a little cup that could be used in zero gravity.) It’s sort of like the pod-based Keurig machines we’re so familiar with down here on Earth, and like the Keurig machine, the ISSpresso produces waste with each brew. That could create a lot of trash in a short amount of time, and getting things on and off the ISS is an expensive process. "We'll see how it goes," Kloeris says. "If it's successful, then we'll have to figure out how we're going to resupply it."

But why go to all this trouble for a cup of coffee? NASA hopes the ISSpresso machine will do more than caffeinate astronauts. It will provide a place for socializing and exchanging ideas, a sort of in-orbit corner cafe. Relaxation is “an aspect that should not be ignored in missions that keep the astronauts away from home for many months in a very challenging environment,” Lavazza says.

“Food provides an important psychological support,” says David Avino, Managing Director of Argotec. “Being able to enjoy a good Italian espresso may be just the right way to finish off the menu designed especially for each astronaut, helping him or her to feel closer to home.”

The ISSpresso machine arrived at the space station with a first batch of just 20 to 30 coffee capsules, so Cristoforetti might want to pace herself.