This Ketchup Will be Sold by the Slice

By Jake Rossen

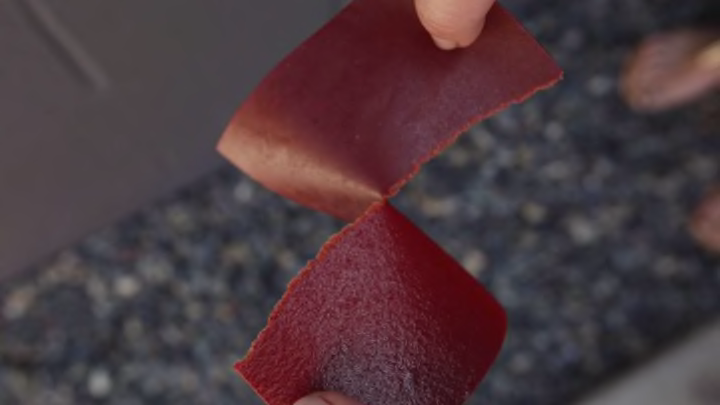

Some have called it a food abomination. Others believe it will be the next big thing in food disruption. It’s ketchup taken out of its customary bottle or squeeze packet and distributed via cheese-like slices. And it may be coming to a store near you.

In March 2018, a company called Bo’s Fine Foods organized a Kickstarter for Slice of Sauce, a new—and highly controversial—method of packaging the condiment. Each retail pouch will contain eight “slices” of dried ketchup that Bo’s argues has several advantages over the bottled version. The ketchup won’t soak a piece of bread or sputter out in watery blasts: Consumers will get an even application of it every time, with the ketchup distributed equally among each bite. Each slice has 30 calories and 5 grams of sugar, with no high-fructose corn syrup or preservatives.

As Vice pointed out, the idea is similar to chef Ernesto Uchimura’s “ketchup leather,” a novelty food hack he created in 2014.

While Slice of Sauce may help prevent apparel-related squirting mishaps, it’s not entirely clear whether people will embrace this rogue approach to dispensing tomato paste. The idea of freezing and then serving slices of peanut butter was met with scorn in 2017. Today reports that some Twitter critics have refused to acknowledge a “ketchup fruit roll-up” while others promise to “make a huge scene” if confronted with it while dining out. We’ll see if Slice of Sauce can dispense some unconventional success when it starts shipping to Kickstarter backers and select retail stores in June.

[h/t Today]