WATCH: The World's Smallest Movie, Starring ... Atoms

By The Week

By Harold Maass

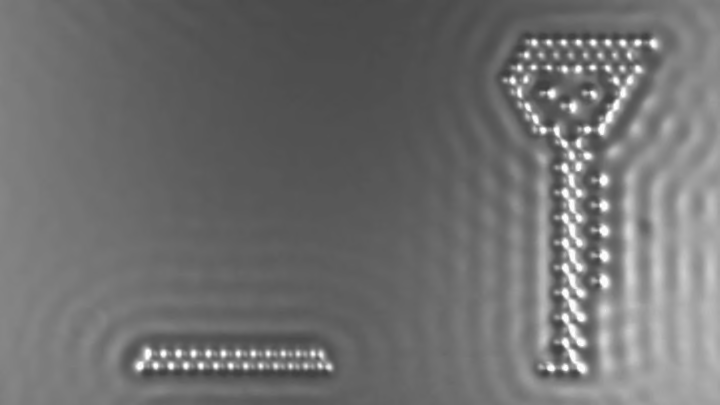

Hollywood loves to go big with movies. IBM scientists went small — very small. The company's researchers produced a short, stop-motion film to showcase their efforts to design the next generation of data storage, and they did it by manipulating individual atoms to create images of a boy playing with a ball and bouncing on a trampoline. The clip, called A Boy and His Atom, has been certified by Guinness World Records as the "Smallest Stop-Motion Film" ever.

The scientists used a tiny needle on the tip of a two-ton scanning tunneling microscope, manipulated remotely by computer, to move carbon monoxide molecules around on a copper plate chilled to 450 degrees below zero Fahrenheit. The frigid temperature "makes life simpler for us," says Andreas Heinrich, IBM's principal scientist for the project. "The atoms hold still. They would move around on their own at room temperature." Each frame involves an area measuring 45 by 25 nanometers (there are 25 million nanometers per inch), but the microscope magnifies the scene over 100 million times.

"This movie is a fun way to share the atomic-scale world," Heinrich says. "The reason we made this was not to convey a scientific message directly, but to engage with students, to prompt them to ask questions." But that's just part of the reasoning. The techniques used to make the movie are similar to those IBM is working on to make data storage smaller as the world's digital archives expand. "As data creation and consumption continue to get bigger," Heinrich says, "data storage needs to get smaller, all the way down to the atomic level."

That sounds logical for computing, but how does this clip stand up as a film? The result is "the worst animated movie I've ever seen," jokes Richi Jennings at Computerworld. "Terrible production values, laughable plot, and awful soundtrack." It's mercifully short, but — sorry, IBM — "two thumbs down." But perhaps reviewers should cut the "IBM eggheads" behind this tiny flick some slack, says Mark Hearn at Engadget. They're just using "a playful spin on microcomputing" to show off the possibilities of thinking small, and in that, they succeeded. "Now that the atom's gone Hollywood, what's next, a molecular entourage?"

More from The Week...

Chickpeas: America's New Cash Crop?

*

Could Online Grocery Shopping Help Save the Planet?

*

7 Jaw-Dropping Images of Storms in Outer Space