Since 1990, the Hubble telescope has brought us photos that are as beautiful as they are scientifically important. But there’s a limit to what Hubble can see—so space agencies from around the world are collaborating to create a better, more powerful, and literally bigger telescope: the James Webb Space Telescope (JWST), which is projected to launch in 2018. In the SXSW panel “Beyond Hubble: Building NASA’s Next Great Telescope,” scientists and engineers discussed what the Webb telescope will look for and all the engineering challenges that go into actually building the instrument.

What JWST Will Do—And How It Will Do It

According to Alberto Conti, Innovation Scientist at the Space Telescope Science Institute, the Webb telescope is a versatile instrument that has four main goals: To find the first stars, study galaxy evolution, study planet formation, and find habitable planets that might contain water (and, therefore, might also have life). “We build telescopes because they’re time machines,” Conti says. “They tell us about how the universe came to be, and how it works.” Scientists hope that Webb will answer questions like: How did the universe form? Is our solar system unique? Are we alone?

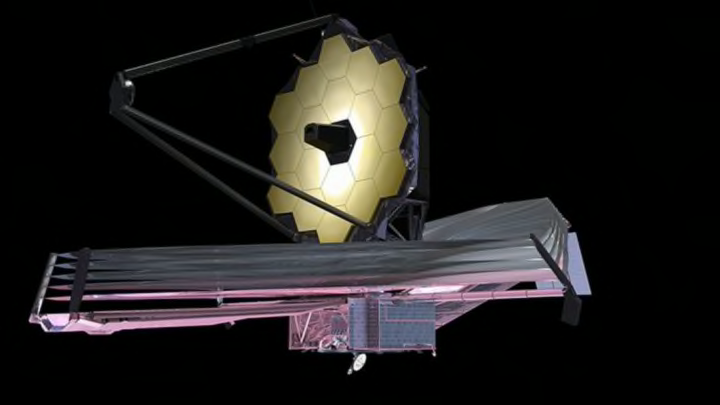

In order to answer these questions, JWST needs to be big—really big. One hundred times more powerful than Hubble, the four-story-tall, infrared optimized telescope will be comprised of 18 hexagonal mirrors that total 21.3 feet in diameter which will allow it to take pictures of faraway worlds, and an 80-foot-long sun shield that will keep the telescope’s eyes cold enough to snap those photos.

While Hubble can capture images of planets the size of Jupiter, JWST will be able to look for planets from the size of Neptune down to the size of Earth, according to Charles Mountain, the director of the Space Science Telescope Institute. And it will do it by looking for infrared spectrums. “On the infrared spectrum, there are three planets that we know a lot about: Venus, Mars, and Earth,” Mountain says. If, using JWST, they can find planets with infrared signatures similar to Earth’s, they might be goldilocks planets—just right to have life. “If we find life, it’ll be as profound as Darwin and Copernicus rolled into one,” Mountain says. “It will bring about a change in our world—we’ll realize we’re not as special that we thought, that evolution happened elsewhere.”

Looking for life begins by looking for stars, because planets that can harbor life will be orbiting around stars. JWST can also use infrared to peer through clouds of gas. “The idea is that we can see thousands of stars embedded in gas clouds because we have the right set of eyes,” Conti says. By looking at the spectra of the disks, Webb will be able to determine what constituents of those disks create planetary systems.

The Engineering Challenges

Building JWST hasn’t been a cakewalk. It has required both creativity and tons of collaboration between scientists, engineers, and companies in the private sector to get it done. Here are the engineering challenges behind key elements of the telescope.

Mirror

In order to see distant objects, JWST needs a big mirror. Blake Marie Bullock, the campaign lead on JWST at Northrup Grumman Corporation, explains the need for a big mirror this way: If you leave a coffee can out overnight in a storm, in the morning, the water in the can will be two inches deep. If you leave out a kiddie pool in the same scenario, the pool will also have water two inches deep—but there will be a lot more water in it. In a telescope, “the same thing is happening with photons,” Bullock says. “If you have a bigger bucket, you can have more photons, and see fainter objects.”

This mirror is so big that it won’t fit in a traditional rocket (Webb will go up in one of the European Space Agency’s Ariane 5 rockets), so engineers had to create a mirror that will fold. “There are 18 hexagons, but three of the hexagons [on each side] are folded down like leaves on a dining room table when it’s stowed,” Bullock says. Once in space, the telescope “unfolds like a flower. Figuring out how this process works takes a lot of engineering.”

Even more complicated is figuring out the prescription. “As you’re manufacturing that mirror on the surface of the Earth, gravity pulls it down and bends that structure,” Bullock says. But when the mirrors are up in space, the gravity is gone—so on Earth, the prescription actually has to be perfectly wrong so that it will be right once the telescope goes into space. As you can imagine, it takes a lot of calculations.

In order to be as precise as the mission requires, JWST’s mirrors have to be very, very smooth. So smooth, Bullock says, that “if you took one of these hexagons and stretched it out to the size of the state of Texas, the biggest bump would be 1 centimeter tall.”

Hot vs. Cold

Infrared is sort of like heat, Bullock says, and because JWST is looking for heat, it doesn’t want to see heat. So engineers are building a five-layer, 80-foot long sun shield that will take photons away from the telescope’s eyes, which much be cold to function. And because there’s such a huge difference in temperature between the hot side of the observatory, where temperatures will reach 185 degrees Fahrenheit, and the cold side, which will be a chilly -388 degrees Fahrenheit, engineers have to think about things like how glue and other materials might behave. Engineers also have to wrestle with how to handle things like the sun shield so that it doesn’t have any creases once it’s deployed.

Weight

The bigger something is, the heavier it is—and the more difficult it is to get it out of Earth’s orbit. JWST is no exception. “As the telescopes get bigger, engineers have to think about how to make it light enough to get into space,” Bullock says. Hubble is just a couple of hundred miles above Earth’s surface, but Webb will be a million miles away, where it is both dark—to make imaging planets and stars easier—and cold (so the telescope functions properly).

Testing

No facility is big enough to test Webb in its entirety, so its components are being tested at Johnson Space Center in Houston, Texas. The facility’s cryogenic chamber, according to Bullock, hasn’t been used since the Apollo missions, so it’s been retrofitted to test JWST’s components. The gold-coated mirrors are being tested six at a time, but the chamber isn’t big enough for the 80-foot sun shield. “That means a lot more math to make sure everything will work the first time,” Bullock says.

Given all of these challenges, how can scientists be sure JWST will work? Nothing is 100 percent, but engineers are working hard to make it happen. “Every piece is tested incrementally, verified, put into a larger system and tested again,” Bullock says. “We’ll spend two years testing it to make sure that it works.”